We only make money when you save

Contact Us

trusted partner

Use cases

All Use Cases

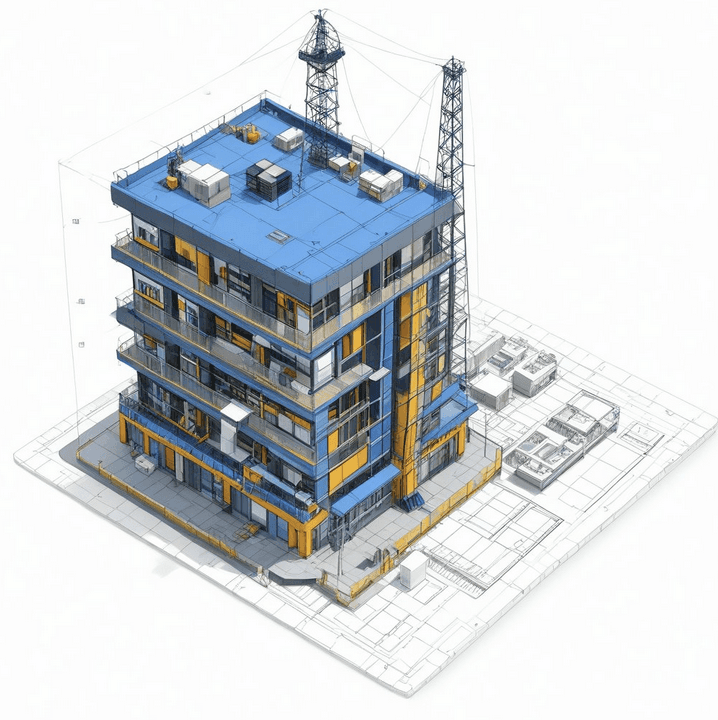

Partner faced with substantial rework costs and schedule overruns due to inaccurate BIM models, especially in MEP (Mechanical, Electrical, and Plumbing) systems.

This case demonstrates that replacing manual MEP verifications with Video-to-Data AI significantly lowers construction overhead, expedites timelines, and creates a reliable data foundation for ongoing predictive maintenance.

Find Out More

Problem: Manually creating a BIM model for large-scale projects was slow and costly.

Solution: AI automated BIM generation from drone video and point cloud data, reducing manual workload.

Results:

• Created a LOD 300 BIM model for a 1,000 m² area in hours

• Improved scalability and project efficiency

Find Out More

AI-Driven Document QA

(Manchester, UK)

Problem: Construction companies faced up to 20% errors in project documentation, leading to costly mistakes and delays.

Solution: AI automated document quality checks, ensuring accuracy across naming conventions, metadata, and compliance.

Results:

• Reduced rework by 90%

• Cut manual verification time by 50%

Find Out More

AI-Powered Bridge Inspection (Global)

Problem: Manual bridge inspections were slow, expensive, and involved safety risks for personnel.

Solution: AI analyzed drone images and 3D scans to detect cracks, corrosion, and structural issues.

Results:

• Inspections completed 5x faster

• Increased defect detection accuracy to 80%+

Find Out More

Problem: Lengthy approval cycles and inefficient coordination between construction phases.

Solution: AI streamlined feasibility studies, procurement, and construction workflows.

Results:

• Reduced administrative overhead by 30%

• Improved decision-making speed by 25%

Find Out More

Structural Engineering & Construction Optimization (Sydney, Australia)

Problem: Manual processes slowed down structural and geotechnical engineering workflows.

Solution: AI automated defect detection, data exchange between platforms, and model optimization.

Results:

• Reduced engineering time by 30%

• Streamlined cross-platform data exchange and analysis

Find Out More

Problem: The municipality needed a comprehensive 3D inventory of its infrastructure for planning and maintenance.

Solution: AI integrated LiDAR, OpenStreetMap data, and aerial imagery to create a Digital Twin.

Results:

• Generated a full 3D city model in 12 days

• Provided real-time data updates for city planning

Find Out More

Problem:

Mining operations suffer from untracked ore loss and undetected process inefficiencies, costing hundreds of thousands annually.

Solution:

AI analyzes site video to detect ore loss, optimize loading, and flag production defects — with 48-hour reporting and heatmaps.

Results:

• Recovered up to 3% of ore, worth $200K/year

• Reduced process-related losses 10-20%

• Delivered ROI, no hardware changes needed

Find Out More

Expertise

Video-to-Data technology enables us to recognize and segment any object in the video and extract valuable data and insights with big data processing technologies

Video-to-Data AI

Automatic labeling of objects in video streams and transforming them into precise models

3D Point Cloud Segmentation

Rapid identification of primary elements (walls, beams) and minor details (pipes, fasteners)

SLAM & Sensor Fusion

Gathering data from drones, LiDAR, and cameras for continuous 3D map updates

Fused BIM Reconstruction

Combining 2D and 3D data to reduce manual labor and enhance BIM accuracy

Neural Radiance Fields (NeRF)

Generating 3D scenes from a minimal set of source images

Predictive Analytics & Monitoring

Forecasting delays, ensuring quality control, and optimizing resource usage

Areas of integration

AI and advanced technologies boost efficiency, reduce costs, and enhance decision-making in various industries

Construction and Engineering

BIM automation, quality control, project timeline prediction, and workflow optimization

Facility Management

Predictive maintenance, energy management, and digital twin creation

Smart Cities and Transportation

Smart grid optimization, traffic flow analysis, and intelligent resource distribution

Manufacturing and Industrial

Defect detection, inventory management, and supply chain optimization

Mining and Extraction

Drone data analysis, safety monitoring, and site condition tracking

continuous learning

At Lepei, we constantly explore the frontier of AI. From Vision-Language Models (VLMs) for real-time 3D segmentation to cutting-edge Neural Radiance Fields (NeRF), our R&D team is shaping the next generation of AI-driven solutions.

Lepei leverages next-generation WildGS-SLAM, a breakthrough in AI-driven spatial understanding that transforms ordinary monocular video into a real-time 3D map with camera positioning—without LiDAR, IMU, or expensive hardware.

Powered by Gaussian Splatting and Bayesian neural networks, this system adapts to dynamic, noisy, and imperfect environments—construction sites, mines, ports, or moving vehicles—where traditional SLAM fails.

Key business benefits:

Cost reduction: replaces costly sensors with standard RGB cameras (e.g., smartphone or CCTV).

Operational reliability: works in dust, fog, motion, and unstable settings.

Deployment flexibility: enables real-time mapping and inspection even in unfinished or hazardous locations.

Data ownership: capture your own spatial data anytime, anywhere, with zero dependency on high-end hardware.

This is SLAM built for reality, enabling companies to digitize, inspect, and navigate physical environments with unprecedented flexibility and scalability.

At Lepei, we’re already integrating these systems to power next-gen inspection, navigation, and digital twin solutions across industrial sectors.

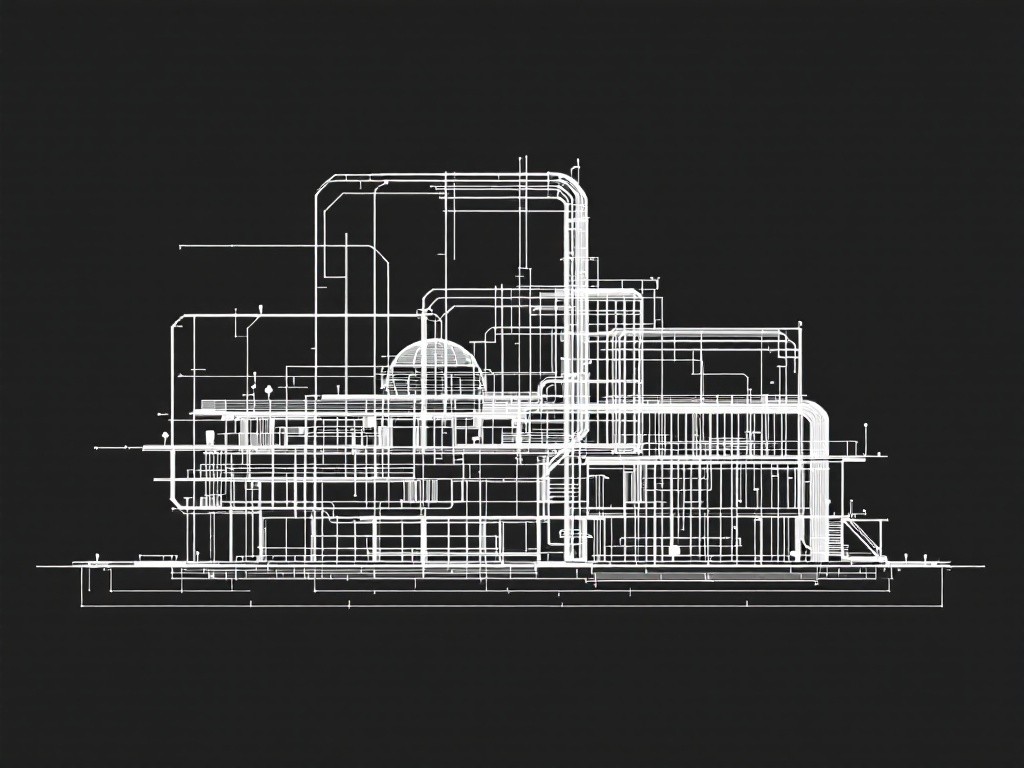

At Lepei, we are applying Segment Anything 3D (SAM-3D) – a powerful fusion of 2D computer vision and 3D spatial data – to extract meaning from complex environments without manual labeling.

How it works:

We take a 3D scan (from LiDAR, photogrammetry, drones).

Project it into 2D → apply Meta’s Segment Anything Model (SAM).

Then project it back into 3D → fully segmented, semantically rich 3D point cloud.

What this enables for businesses:

No BIM or annotations needed to extract key structures (walls, doors, windows, pipes).

Accelerated digital inventory of buildings, industrial sites, or mines.

Automatic compliance checks between design plans and as-built conditions.

Faster onboarding of brownfield assets into digital workflows or twin systems.

This is a game-changer for industrial environments where speed, cost, and automation matter.

At Lepei, we’re already using SAM-3D to bridge the gap between raw 3D data and intelligent decision-making—with no BIM dependency, and no manual overhead.

How it works

What Awaits You with Lepei?

We’re not about complicating things. Here’s our simple 4-step journey to elevate your project with AI.

Discovery & Consultation

Plan & Propose

Implement & Integrate

Monitor & Optimize

Get In Touch